您所在的位置是:进出口服务网 > 推荐产品 > mineral wool board production line

mineral wool board production line

发布企业: 中泰锐意有限公司 | 发布时间:2010/8/10 10:14:39

- 发布人:

- 中泰锐意实业有限公司

- 联系电话:

- +86-0311-86811937

- 产品型号:CJA237-W-110/2X12.5 SFW2000-

- 官方报价:0.0000

- 品牌:天成

- 产地:天成

| 年 |

01

02

03

04

05

06 07 08 09 10 11 12 |

全年 |

产品介绍:

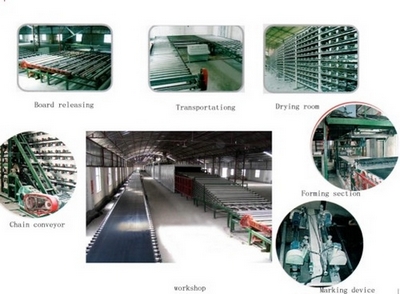

This production line has the advantages of high automatic degree, low cost, easy operation, and little investment. It covers little land, consumes few fuel, has no pollution, but it can bring in fast return and big profit.

Mineral wool plant flow chart: loosen the mineral wool, rub the paper and make the liquid thick, mix the raw material, enter the constant position, thick liquid out to the net, shape out and go into the drier room, raw board out cut (from 2.4mm to 1.2mm), blow talcum powder and enter the second drier room, Spurts Factory-applied vinyl latex paint, Embossed, Second cut into aimed sizes(600mm*600mm), Painting back rubber(w-r), package and then put into the warehouse.

The mineral wool board produced by this line is a kind of safe and environment friendly construction product, taking the high qualified granular mineral wool as the main raw material and does no harm to human body. Main advantages: elegant decorating effect, fireproofing, moisture resistance, heat insulation, and soundproof.

mineral fibe....

The mineral wool board produced by this line is a kind of safe and environment friendly construction product, taking the high qualified granular mineral wool as the main raw material and does no harm to human body. Main advantages: elegant decorating effect, fireproofing, moisture resistance, heat insulation, and soundproof. We can provide the through-train service according to customers' requirements, including the design, instruction, installation, adjustment, and the prescription till you can produce the qualified product. The slag wool is a kind of inorganic fiber taking the industrial slag (blast furnace slag, phosphorus slag and fly ash) as the main raw material, and goes through the processes of remeltment and fibrosis, while the crag wool is a kind of inorganic fiber which takes the natural rocks such as Basalt, diabase, andesite as the basic raw materials, and melted and fibrosised. The above-mentioned fiber can be made into board, pipe, felt, belt, paper and many other good qualified materials which are high temperature resistant, heat insulation and sound absorption. And they are applied to the construction and industrial equipments (pipe, container, and kinds of kilns) for their heat insulation, fire prevention sound absorption, and shaking resistance.

mineral fibe....

This production line has the advantages of high automatic degree, low cost, easy operation, and little investment. It covers little land, consumes few fuel, has no pollution, but it can bring in fast return and big profit.Mineral wool plant flow chart: loosen the mineral wool, rub the paper and make the liquid thick, mix the raw material, enter the constant position, thick liquid out to the net, shape out and go into the drier room, raw board out cut (from 2.4mm to 1.2mm), blow talcum powder and enter the second drier room, Spurts Factory-applied vinyl latex paint, Embossed, Second cut into aimed sizes(600mm*600mm), Painting back rubber(w-r), package and then put into the warehouse. The mineral wool board produced by this line is a kind of safe and environment friendly construction product, taking the high qualified granular mineral wool as the main raw material and does no harm to human body. Main advantages: elegant decorating effect, fireproofing, moisture resistance, heat insulation, and soundproof. We can provide the through-train service according to customers' requirements, including the design, instruction, installation, adjustment, and the prescription till you can produce the qualified product.

gypsum board....

characteristics: highly automatic, convenient, less investment Gypsum board machine:Production plan: Plasterboard, being conformity with GB/T9975-1999(equal to European Standard).Specifications:thickness:8, 9.5, 12, 15mmwidth:1200mmlength:2400--3600mmvariety:normal plasterboardWe are a company specialized in manufacturing and designing the gypsum board production line of automatic & semi-automatic with annual output from 2million to 50million square meter and we can offer complete sets of gypsum board production machine, We could design a gypsum board production line with detailed equipment technical processes, workshop detailed plan according to your practical condition. We win many clients' trust by focus on the optimizing equipment design, using fewer land, simple craft, easy operating, reasonable price, and high quality.

gypsum board....

We have the strong engineer team,and the strong technical supporting team. we can work out the best design proposal of production line according to customers' requires and needs. What's more, our company has professional installation teams and provide the accessories all the year round. We are also responsible for the technical consultation and services and solve all kinds of technical problems at any moment. We can offer some help for the consignment and the relevant procedure on import and export. Our best machinery and equipments in good quality ,considerable price and good after-sale service should be your best choice .If you are interested in our products ,please contact us without hesitation.we'll be looking forward to our best cooperation! TEL/FAX:+86-0311-86811937Skype: machinery5861Yahoo:seiko168@hotmail.comMSN:ztryl@hotmail.comWeb: http://www.ztry168.comJianshe North Street Shijiazhuang City Hebei Province . China Zhongtairuiyi Industry Co.Ltd

更多

服务热线:010-89438819 京ICP备12042581-2

进出口服务网(www.ciedata.com)版权所有 2009